A brake pad is a part of any braking system that interacts with the braking surface of the wheel itself or wheel rim (like in a bicycle) or the surface of a special brake disc (like in a car) by pressing. When you press it, the car loses speed and slows down until it comes to a halt.

The pad is made of a special compound and is attached to a hard metal base. Each company has its own composition, which is kept in the strictest confidence.

The main thing is that the pad should be wear-resistant (it should last the maximum number of miles) and at the same time it should not damage the brake disk of the car, it should also withstand the maximum temperatures and not collapse (because the disks are superheated while braking). Such pads are attached to the brake plate either with special clips or with very strong adhesives that can withstand the load and temperature.

Why are my new brake pads burning?

You would be surprised, but it is quite common for them to smoke after replacement. Brakes getting hot after new pads is known as the polymerization or curing process. Normal breaking leads to the heating of the friction materials which makes the pads go through this final curing process. So in this case, nothing is burning up, the brakes smelling after new pads is not the result of oxidation, it is the result of gasses produced during the curing process.

The polymerization or curing process is necessary if new brake pads are heated too quickly or beyond a certain heat level, because in this case the friction material can lose its strength and the off-gassing can lead to brake fade.

That is why avoid stomping right after a brake job unless this is necessary, i.e. specifically recommended by the manufacturer. It is recommended for some pads to brake from high speeds, but those are pads specifically designed for racing. Street brake friction material is not broken in or cured using this process.

Is it normal to smell burning after changing brakes?

Smell always indicates that you have overheated brakes. Such smell can be caused either by emergency brake that was left on while driving or by new front brakes “breaking-in”. Emergency brake operating while driving can lead to hot brakes and a foul odor. Luckily, there is a simple solution to this problem – just disengage the brake and continue to drive as usual. But check the rear brakes, just in case, especially if you drove a long distance with the emergency brake on.

When speaking about new brakes, they can emit a smell for a couple of hours after installation. However, be careful – if you can smell it after many hours, it is better to check your front brakes’ calipers. It usually happens when you don’t check braking hardware before installing the new pads. The solution is also quite simple – you should replace the hardware and the smell will disappear.

However, the smell is also caused by a number of other malfunctions. For example, oil leaks between the box and the engine when braking can also cause the smell of burning. It can also happen when a person who changes your brake pads uses the wrong kind of grease which causes the burning smell.

What would cause a rim to get hot?

Brake disk is an executive mechanism of the brake system. When rotating with the wheels, they take over the friction of the pads. When the rotational energy converts to heat, the car slows down until it comes to a halt. Sometimes drivers notice that the brake discs are overheating and wonder why the heating is occurring and whether it is a sign that the car requires repair work.

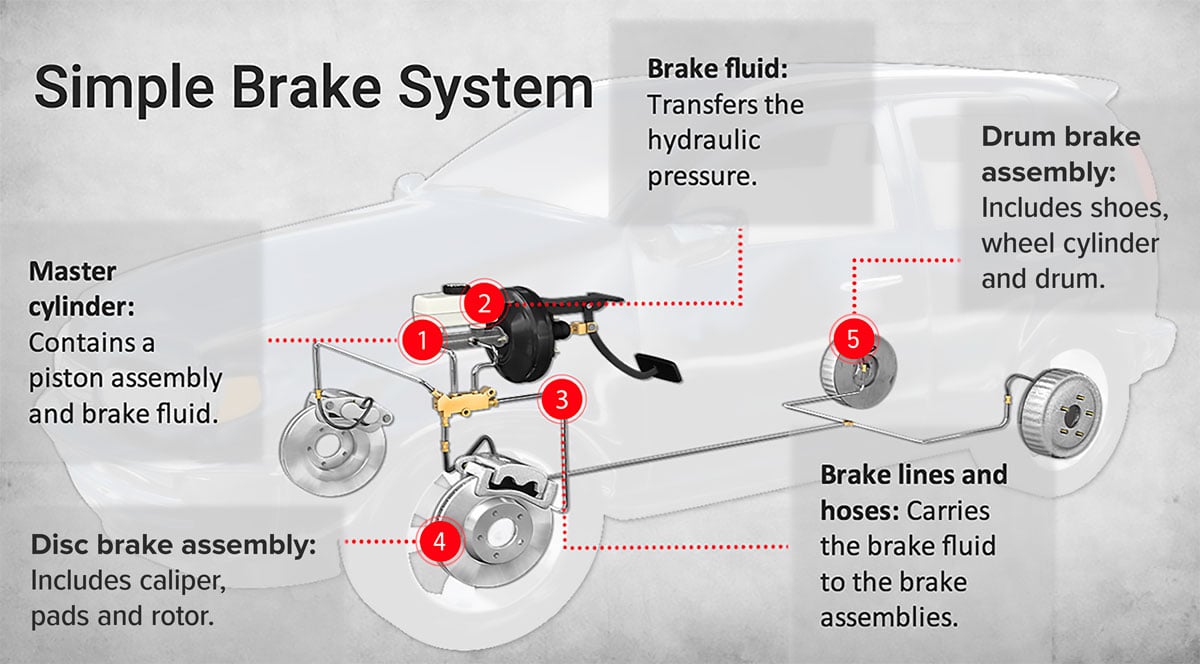

Brake discs in the automotive industry began to be actively used in the middle of the last century. Initially, they were put only on the front wheels, but over time, there appeared cars with rear disc brakes. The principle of a brake unit is extremely simple.

When the brake pedal is pressed, a special fluid transmits the force to the working cylinders. These, in turn, “press” the brake pads against the discs and friction ensures braking.

It is clear to those familiar with physics that a considerable amount of heat is generated during friction. Cast iron or steel discs have become more complex over time in order to ensure the best possible removal of friction. Today, for example, ventilated brake discs are widely used, which consist of two parts connected by blades. They create an air stream, and the perforated surface helps to remove dirt particles arising from the abrasion of friction materials or dust from the environment.

It is clear from the principle of car brakes that heating during this process is a usual thing. Operating temperatures in cars can be as high as 570 F. In sports cars, which are used to heavy braking, operating temperatures are even several times higher.

It seems logical that the more often you have to press the pedal, the harder the brakes will heat up. You should also remember that if you like jamming on the brakes then overheating of the system is also possible. When the operating temperature is above its limit, it leads to increasing wear and braking efficiency being reduced by several times, which extends the braking distance and increases the time of emergency stopping.

Among the most negative consequences of overheating is the deformation of the discs, which will require a groove or, in the worst case, replacement to level it out.

However, excessive heat in the brakes may not only be caused by the operating conditions. Among its most common causes are:

- it can be the result of a recent pad change, the temperature will return to normal after the pads ‘breaking in’

- the critical level of brake discs wear and tear;

- low- quality brake pads;

- problems with rear brakes: the entire braking force is in front of the car;

- jamming of the pads.

Inexperienced drivers cannot always measure the temperature of the vehicle (they often forget to do it). Possible malfunctions due to overheating can be indicated via:

- steering wheel vibrations;

- jerks;

- unusual sounds when braking.

You should never ignore overheating, as well as other problems with the braking system, since it can be dangerous. You should also replace brake discs regularly according to the manufacturer recommendations.

Add comment