Transmission is one of the automobile systems having various units and details in its composition. Their main task is to transfer force from the motor to the drive axle.

If a manual gearbox has a simple design, the automatic transmission has more units and assemblies, which in turn affects the cost of its manufacture, repair and operation. However, such a gearbox is more convenient to use, especially when driving in the city, because it does not require constant switching on/off the clutch. In this way, human involvement in the automatic transmission is minimized.

Also, today the customer can choose from several types of automatic transmissions:

- hydro-mechanical gearbox (conventional “automatic”)

- manual transmission with two clutches

- robotic gearbox

- CVT

Each of these types of transmissions has its pros and cons.

Among the advantages is that it is easy to use (no need to constantly engage the clutch), it has no risk of overloading the motor (the automatic gearbox itself selects the best moment to shift to a higher or lower gear). Also, it has shortened time between the lower to higher and back shifts without loss of motor power.

However, such type is known for expensive repair and maintenance, a heavy weight of the unit (compared to a manual gearbox) as well as relatively low vehicle injectivity (most typical for hydraulic transmissions). You are also unable to tow the vehicle with a flexible or rigid coupling (only with a tow truck).

What would cause a 4L60E transmission not to shift?

An automatic transmission, while being quite sensitive to incorrect operation of the unit, may occasionally operate incorrectly, in particular not to change gears.

But first of all, it is necessary to make sure that this malfunction is related to the work of the unit. You must be sure that all vehicle systems function properly when you are unable to change gears.

One of the major faults for which the automatic transmission does not change gears is often the lack of fluid in the system. This is usually due to a worn-out machine oil seal, which causes the fluid to leave the automatic transmission.

Other breakdowns include:

- Need for friction replacement, piston cuff breakage, clutch rings failure or hydraulic block valve jamming.

- Friction breakage, piston cuff failure, wear of O-rings, clutch drum slotted connection failure or other failure associated with this assembly.

- Brake cuff malfunctions, brake lip piston rod malfunctions or wear brake package malfunctions.

You can also use a 4L60E troubleshooting chart that will help you detect a malfunction.

Is the 4L60E a good transmission?

The main problems are the rapid wear and tear of the converter lock. Its friction wear products clog the solenoids as well as the hydro block channels. Here, the torque converter operates in an unusually stressful mode, disperse the powerful machine by locking when the driver presses the gas pedal hard into the floor. Another weakness of this transmission is the clutch package 3-4.

Also, many complaints include the destruction of a planetary row of one of the transmissions. It is usually the result of overload and its overheating. By the way, the temperature of the unit (4L60E) is important, not less than that of the engine, so it is necessary to keep clean not only the main cooling radiator but also an additional radiator transmission (if available).

If you intend to use the vehicle in a hot climate, with a constant load (full saloon, trailer, etc.), or for heavy-duty (off-road driving, etc.) – it is recommended installing an additional radiator for the transmission (there are even models with a built-in thermostat and a separate fan).

How much does it cost to rebuild a 4L60E transmission?

Since 1993, the 4L60E has undergone several changes – in the control system, in the principle of the torque converter lock. There have also been changes in the clock frequency of the pressure regulator, i.e. the hydro block and solenoid resistance.

Aluminium pistons were abandoned, and the TCM unit was changed by switching the box design to steel rubberized pistons. Since 1998 the body of the unit became separate and consisted of the main body, bell and shank adapter.

On cars from 2007-2010, the GMT900 body is characterized by a microcrack in the clutch body 3-5 reverse, the rear gear disappears and the ACS starts to work incorrectly in third and fifth gears. In connection with this factory, the welding process of this case was changed by the manufacturer and the pump was modified. In later models, this failure is much less common.

If you have a shop pull, rebuild, and reinstall the transmission it can be from $2000 – $4000 . To rebuild it will take 6 hours.

What are the symptoms of a bad transmission solenoid?

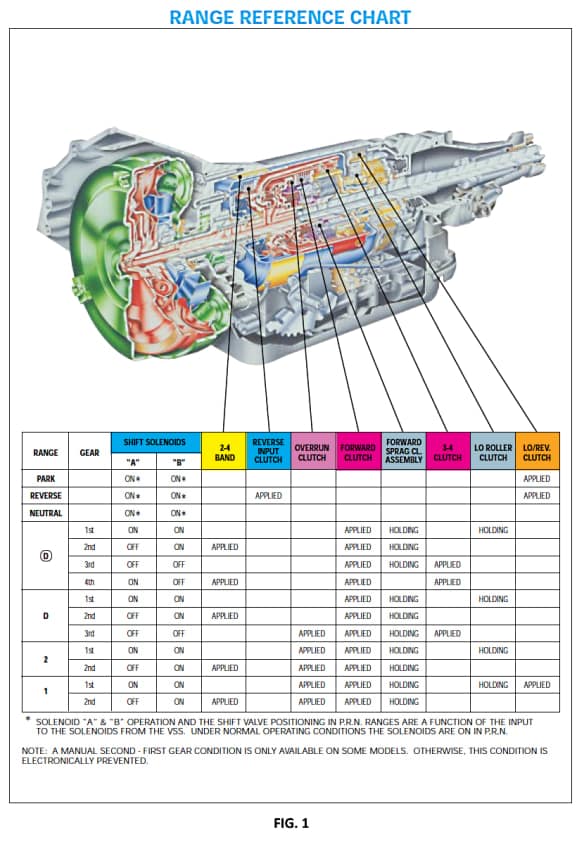

A solenoid is an electromagnetic valve. It reports to the ECU (control unit), opening/closing a channel in the valve plate during transmission. Its main task is to direct the oil pressure into a certain clutch package, to quickly change gears and to activate or deactivate the hydraulic transformer lock.

The reason for breakdowns of solenoids is poor quality oil. Solenoids are clogged with soot from paper, steel, bronze and aluminium dust, which is derived from worn-out consumables and components. The problem is that the solenoid valve works normally when the oil is cold and brakes when it is hot. To eliminate this problem, it is recommended to rinse the solenoid, rinse in solvents and clean with alternating current and solvent.

Leakages are the result of wear and tear, and breakage of parts such as plunger and manifold. When one of them is weakened, the computer takes into account its wear and redirects some of the load to other solenoids. Another common cause of solenoid failure is the wear and tear of its parts: bushings, core tube, hanger spring or a bonnet.

Add comment